Organic Tomato & Bell Peppers

The Effect of Super-oxygenated Water Supplied by Drip Irrigation on Vegetable Production.

May Farm, CSA, Minnesota | Summer 2006

Prepared by: A.H. Markhart for Ovation Science

Plant Performance

Two varieties of heirloom tomatoes and one variety of bell pepper, cucumber, and muskmelon were grown according to USDA National Organic Standards in soil under a 30 by 90 foot hoop house at the May Farm, Marine on St. Croix, MN. All water was supplied by drip irrigation, and a fish emulsion fertilizer was applied at transplant. Irrigation water was supplied from an on-site well that delivered water that varied in oxygen concentration from 12% of saturation to 33% saturation during the growing season. The irrigation stream was divided as it entered the hoop house. Half of the water was oxygenated to130% to 150% of saturation using two flow-through electrolysis units at a flow rate of 0.5 gallon per minute per unit. Control water was passed through identical units that were not powered and therefore did not effect the composition or temperature of the irrigation water. Water was then directed to drip tapes laid in a grid to provide four blocks of treated and non-treated experimental units per vegetable variety. Each block consisted of 5 plants. The center three plants from each block were harvested and all fruit counted and weighed throughout the growing season.

The experiment suffered from production problems that significantly impacted the statistical significance of the results. Pruning and rodent issues caused complete cucumber and melon crop failure. Colorado potato beetle infestation destroyed one block of one tomato variety and variable plant establishment impacted both tomatoes and peppers. However, both varieties of tomatoes and the bell peppers grew well and yielded very high quality fruit.

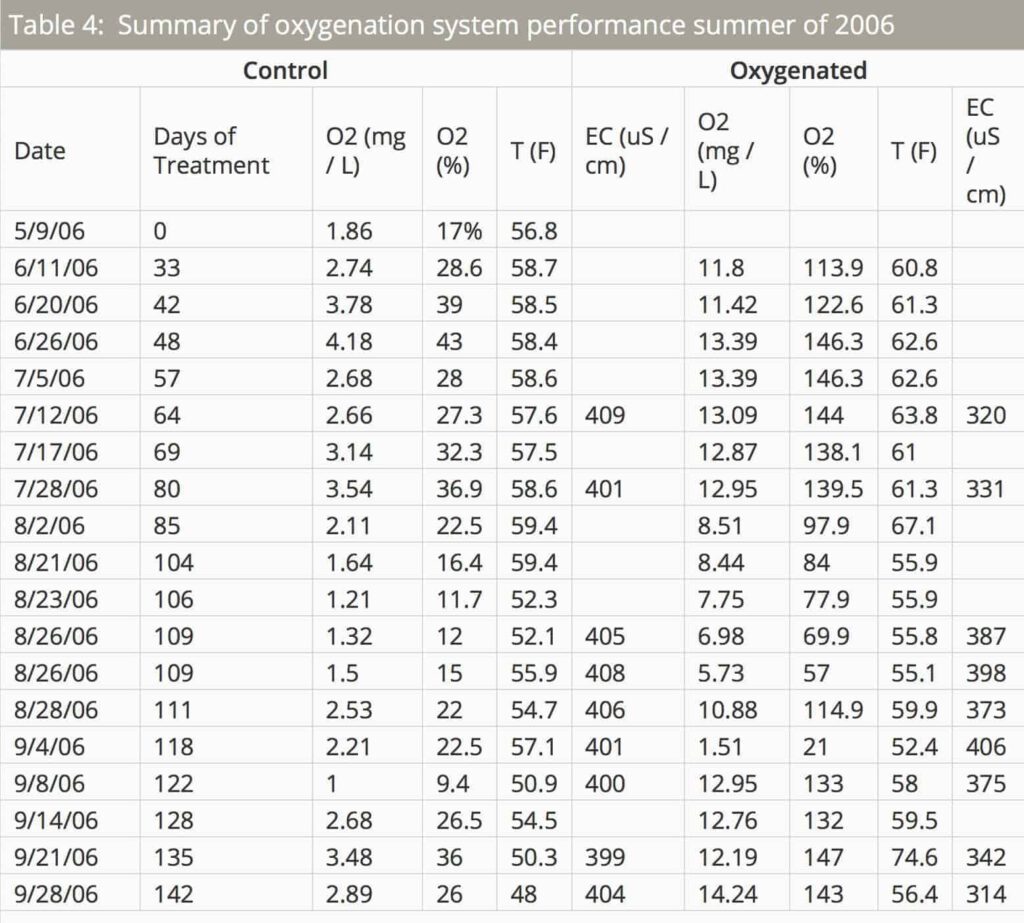

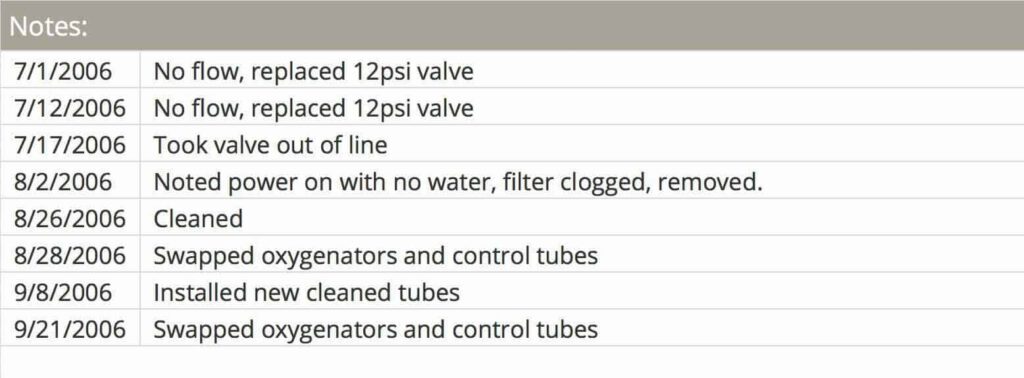

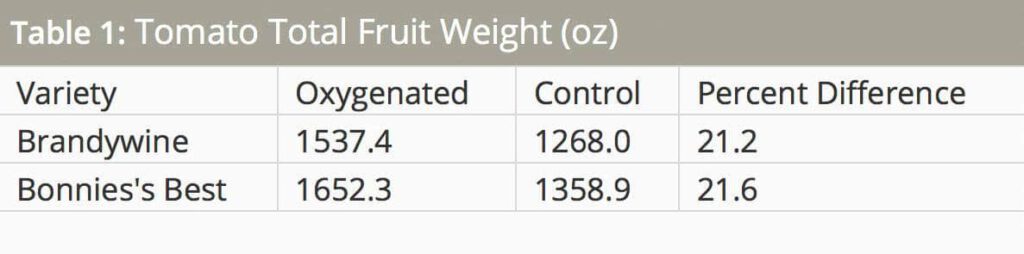

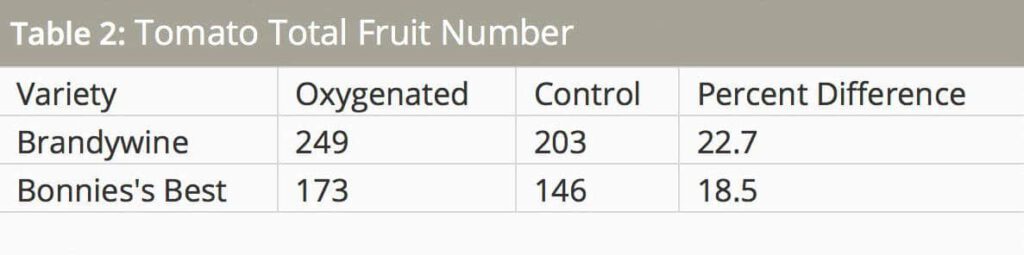

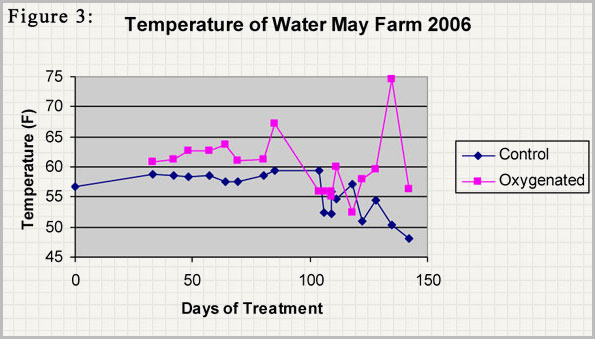

Despite these experimental “learning opportunities” the results yielded interesting and consistent trends. At all harvests for both the tomatoes and the peppers the oxygenated plants had a greater yield (total fruit weight) than the control plants and more harvestable fruit (Tables 1,2,3). For tomato the increase in yield was due to an increase in the number of harvestable fruit. The average size of the tomato fruit was not affected by oxygenating the irrigation water. For peppers, however, the increase in yield was due to an increase in the number of harvestable fruit and size of the average fruit.

Oxygenator Performance

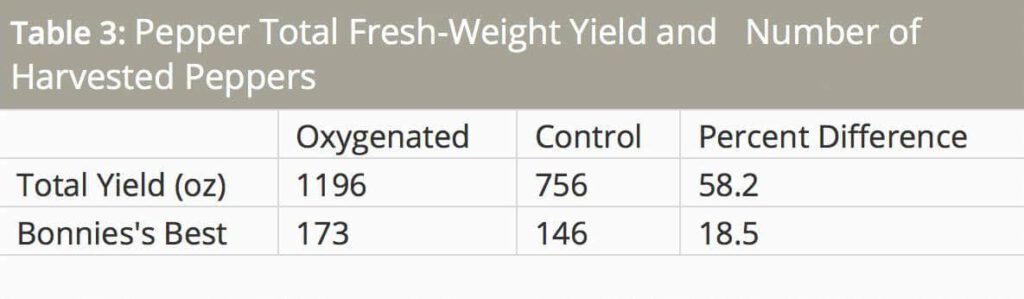

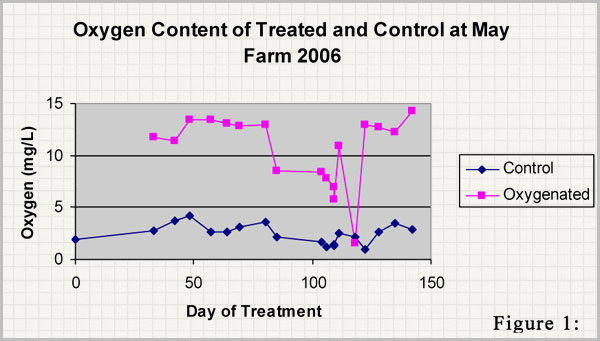

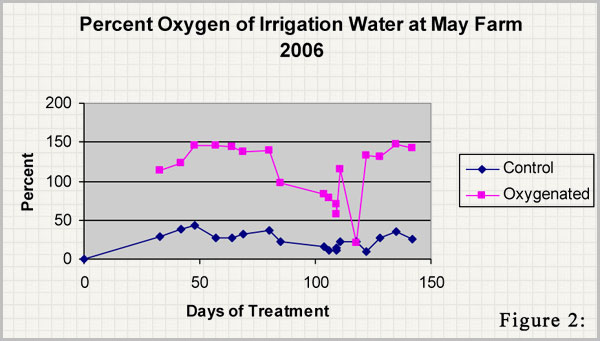

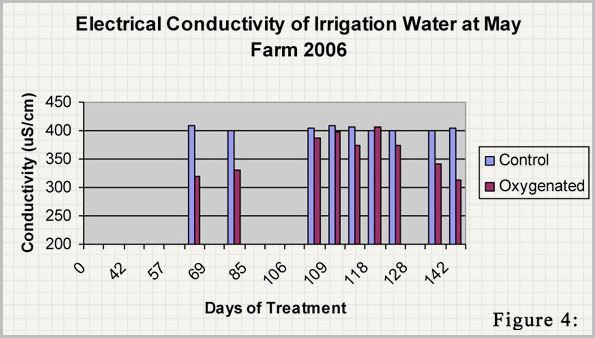

Once installed and plumbed to deal with the water supply from the May Farm well, the oxygenators worked very well. Periodically during the growing season dissolved oxygen concentration, temperature, and electrical conductivity was measured for the oxygenated water and the control water (Table 4, Figures 1-4). Plants were irrigated at the farmer’s discretion. The farmer did not keep accurate records as to frequency and duration of irrigation events. Observations suggest that he watered the plants adequately for good growth, but was not luxuriant with water application.

Irrigation rates were set with flow meters to 0.5 gal per min through each of the oxygenators producing a 1.0 gal per min of water applied to the oxygenated plants and to the control plants. The oxygenators increased the oxygen level in the water to about 140% for the first 80 days of the experiment and then showed a slow decline over the next 30 days until the units were thoroughly cleaned. Cleaning restored performance.

The oxygenators also increased the irrigation water several degrees and decreased the EC compared to the control water. The effect of either of these changes in water supply on plant growth are unknown, but were not negative in this experiment.

There was significant iron and/or silt that came from the well. This contamination caused problems with the pre-filter and pressure valve. During the last half of the experiment the pressure was regulated at the well head and flow by the metering valves.

Summary

The first season using flow through oxygenators to increase the dissolved oxygen in drip irrigation water provided extremely useful information on both plant and equipment performance. The equipment was adequate to supply a 30 by 90 foot greenhouse with oxygenated water. Increased maintenance convenience and better ergonomics will produce a farm friendly technique for increasing the oxygen content of drip irrigated water. Although experimental and production issues resulted in a loss of statistical significance, the trends in plant performance were positive with increased yields in bell pepper and tomatoes and increased fruit size in peppers.

Table 1: Tomato

Table 2: Tomato

Table 3: Pepper

Figure 1:

Figure 2:

Figure 3:

Figure 4:

Table 4: Summary