Vertical Hydroponics

Biofilm control and much more...

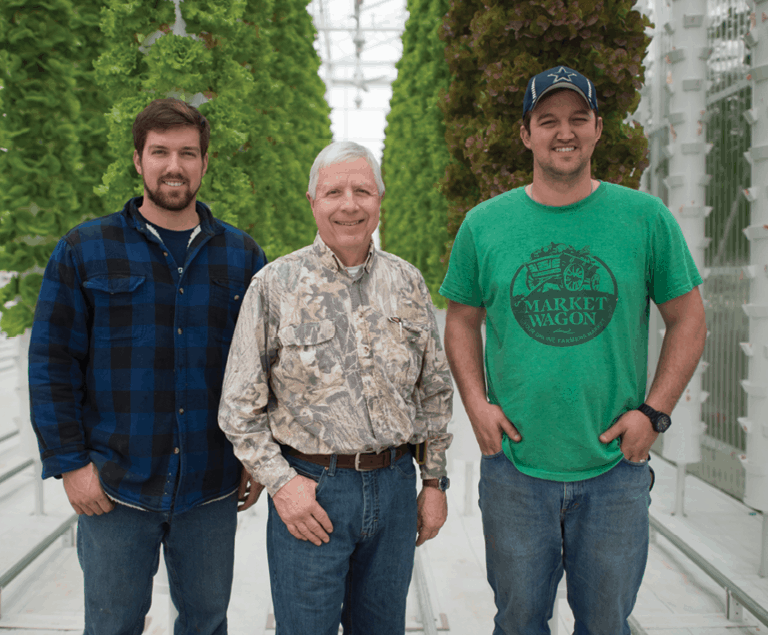

Micro Farms LLC of Indiana

While initially doing research on using DO to help control biofilm, Dion Graber, owner of Microfarms, LLC in Indiana noticed a marked difference in yields out of his produce. He’s gone all in, using O2Grow’s largest oxygenator, the O2Grow-2250 to add DO to his irrigation tank for all of his plants. The market farmer, who provides fresh produce to local markets, says he’s seen an increase of 40% in tomato production, 50% in cucumbers and 60% in peppers. He says they’re also experiencing earlier harvests of lettuce (5-6 days earlier) out of their hydroponic system.